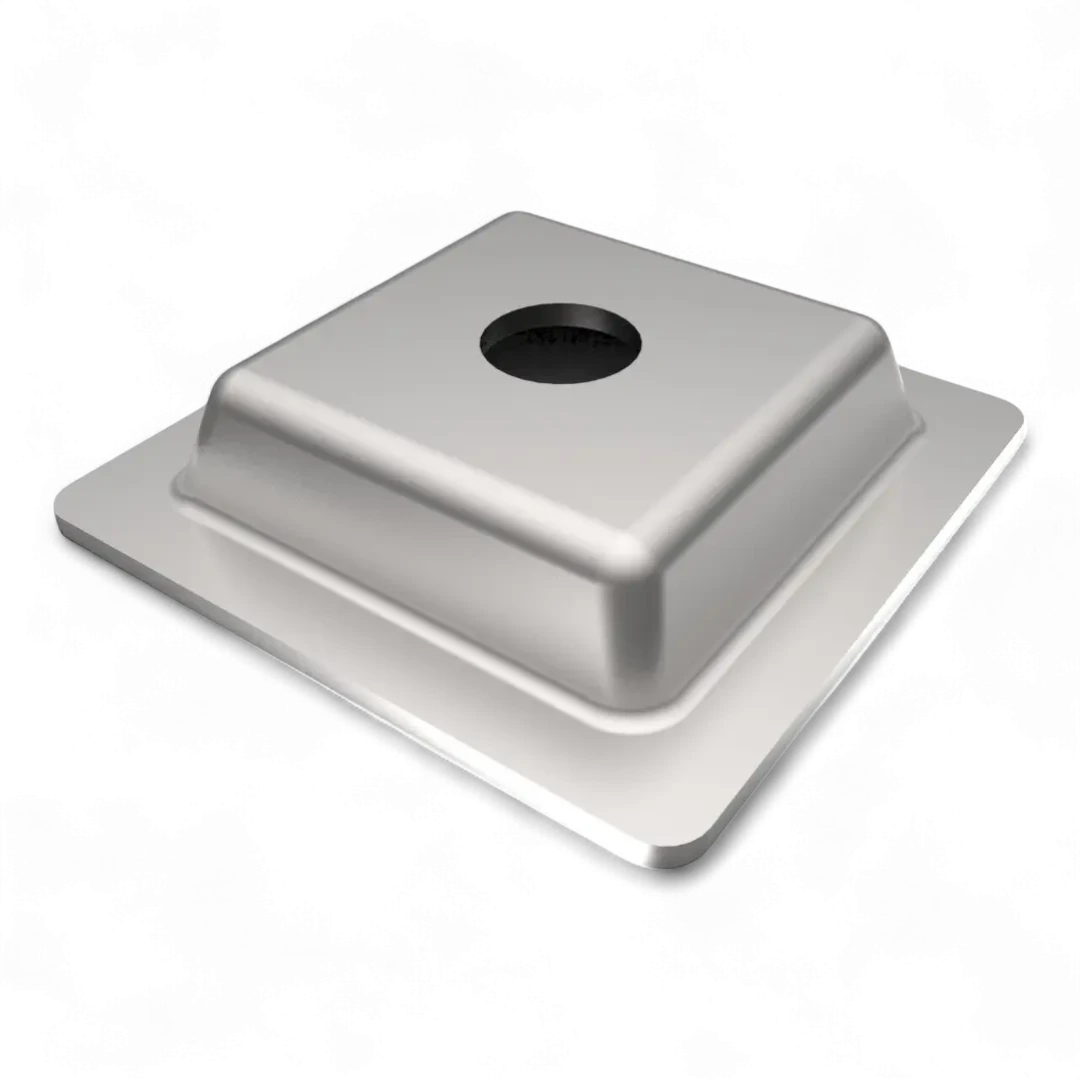

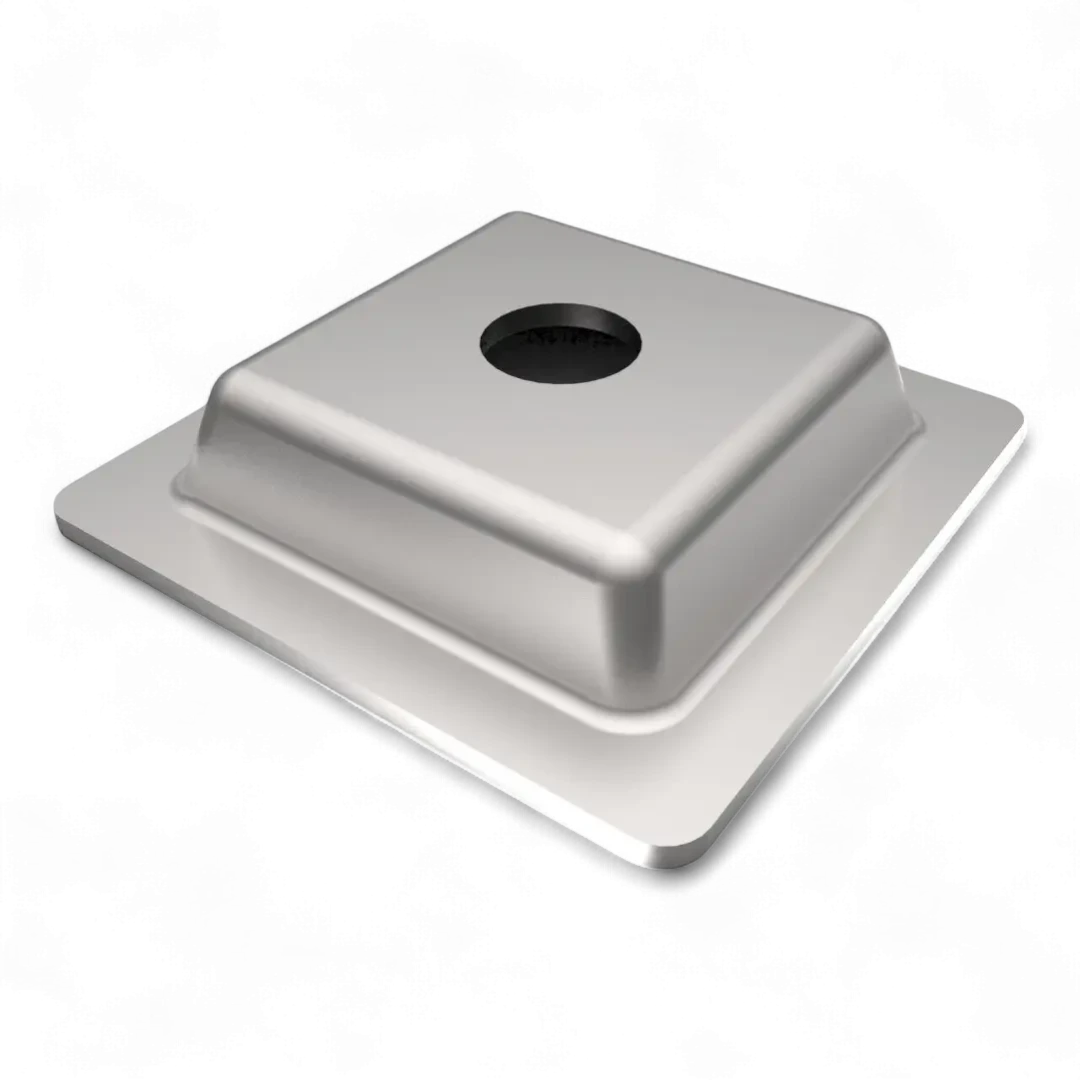

Plate base

Type: Accesories

Model: Plate base

Load capacity: without

Castors: without

€5,20 exkl. MwSt.

€6,19 inkl. MwSt.

SKU:TFQ-116x116x29-00

Couldn't load pickup availability

Features and options

- Material: 1.0037 (S235JR) blank

- Special dimensions possible

- Sale from 100 pieces

Product description

plate base

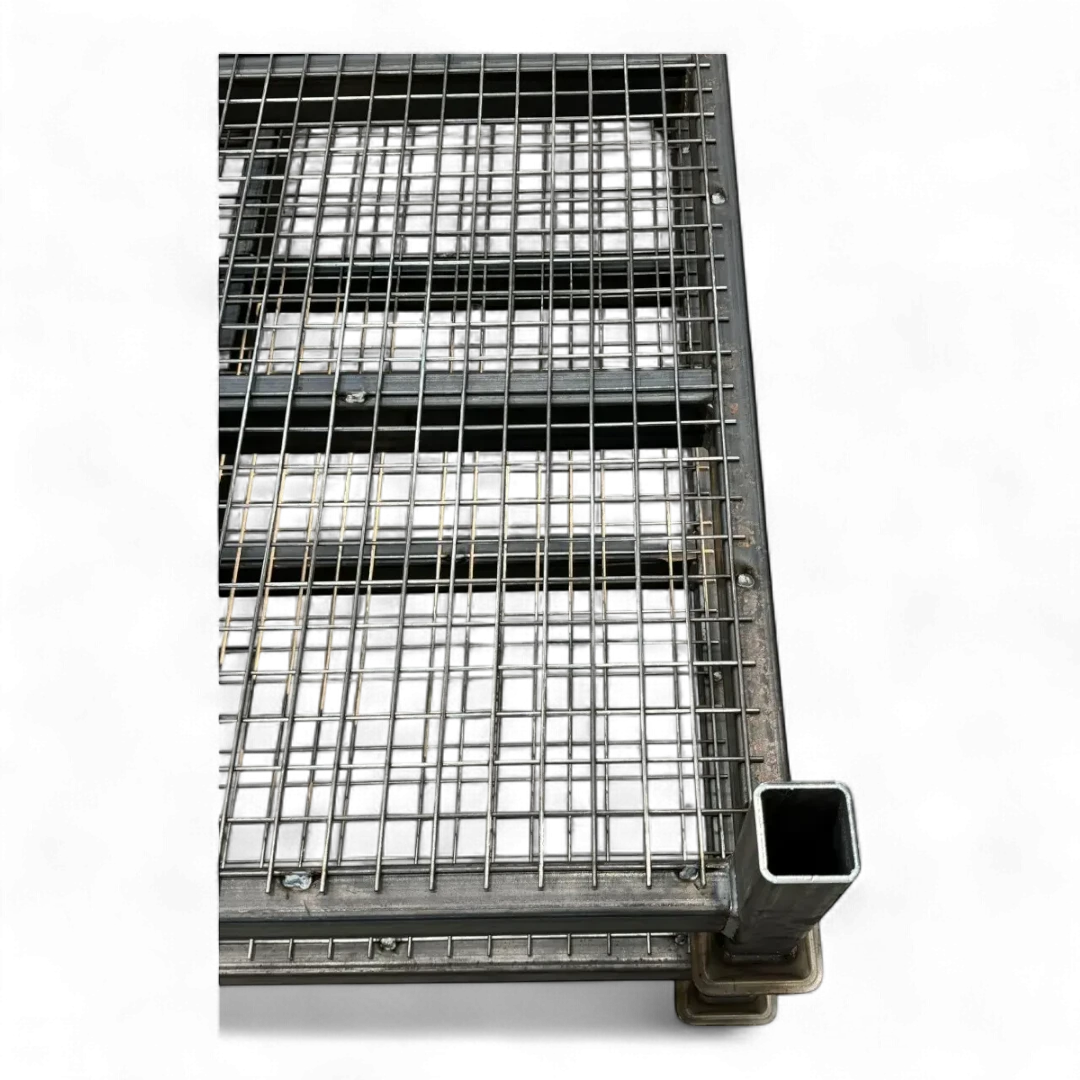

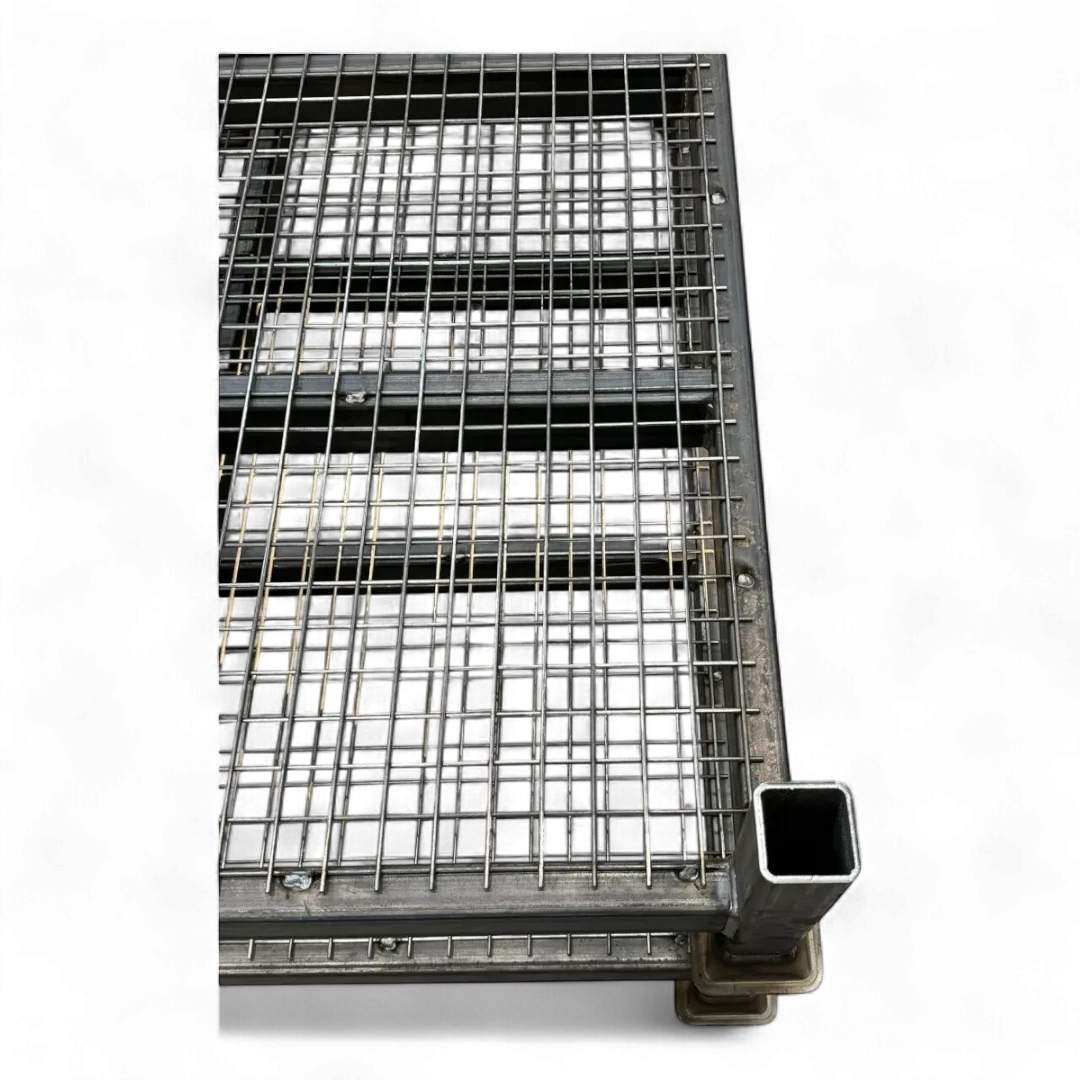

Secure stacking, easy positioning. Our solid S235JR steel stacking plates for welding are the upgrade for your pallet stackers. Replace outdated stacking corners with maximum stability, self-centering, and floor-friendly load distribution.

The upgrade for your steel construction: plate base instead of stacking corner

Stacking corners used to be the standard – but designers know better now. Stacking corners are difficult to position and offer little margin for error. Our plate feet solve this problem through intelligent geometry:

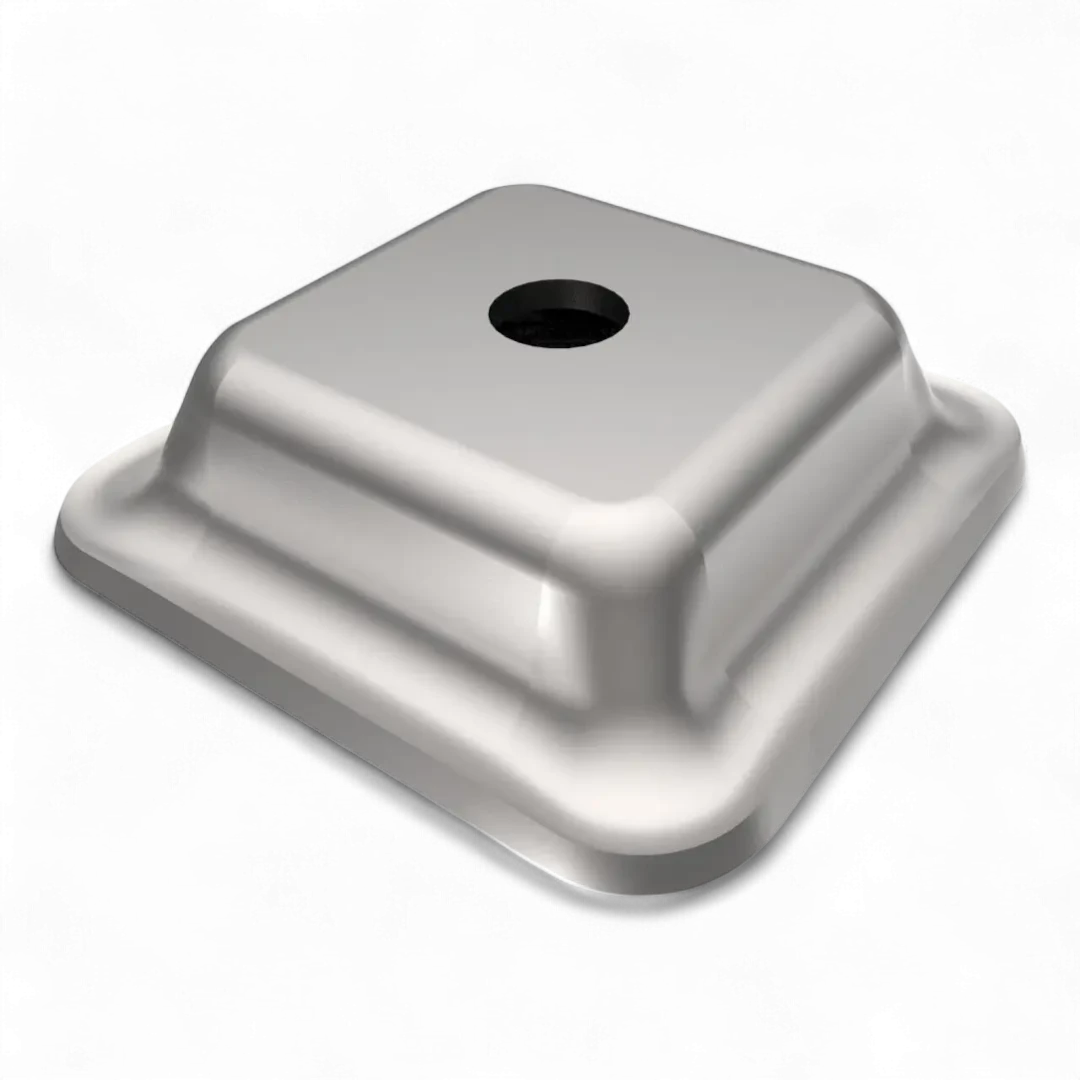

- Self-centering (funnel/pyramid shape): Thanks to their special shape, the stanchions automatically slide into the correct position during stacking. This saves time and prevents damage during forklift handling.

- Floor protection: The enlarged contact area distributes the weight better than concentrated corners. Ideal for sensitive hall floors or asphalt.

- Easily weldable: Made from structural steel S235JR, ideal for all common welding processes.

Technical Data & Load

We offer flexibility for your design. Suitable for welding onto round and square tubes up to 90 mm .

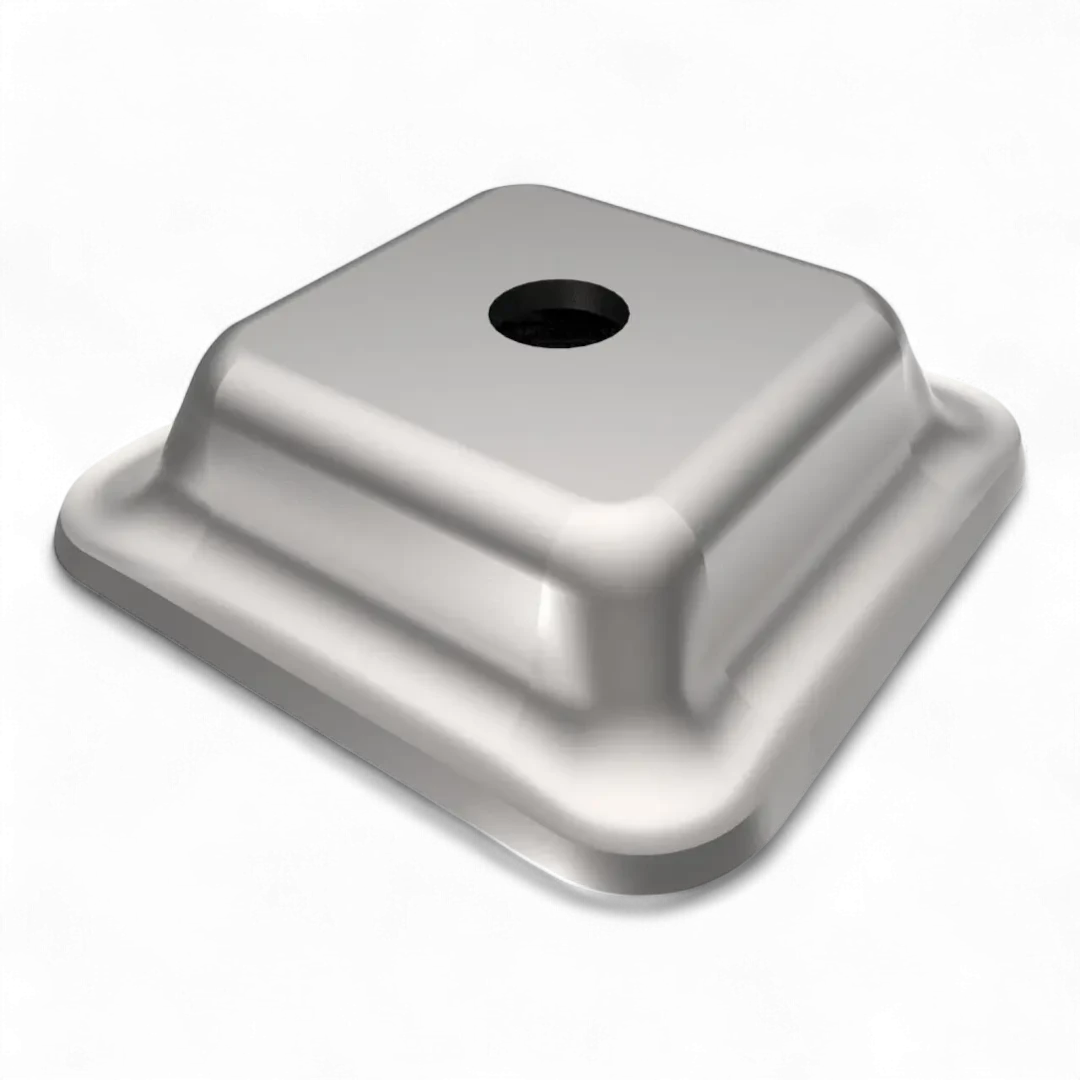

Variant: Square plate feet (pyramid shape)

Designed for extreme loads. The load-bearing capacity varies depending on the buckling length (height of the load carrier):

| Load carriers up to 700 mm in height: | up to 90 kN (~9 tons) |

| Load carriers up to 2000 mm in height: | up to 30 kN (~3 tons) |

Variant: Round plate feet (funnel shape)

The classic choice for pipe constructions.

- Suitable for various pipe diameters.

- Load capacity: Standard from 1,500 kg per load carrier.

- Available in 3 sizes.

💡 Professional feature: Design for galvanizing

Are you planning to hot-dip galvanize your frames after welding? Choose our version with zinc drain holes . This prevents dangerous air pockets and ensures clean drainage of the liquid zinc – for perfect corrosion protection without any rework.

Looking for a lighter solution for compact containers? Click here for our stacking pins.

Do you need a tiered pricing list for series production? Click on "Request a quote" above.